Desktop Metal 3D Metal Printing Shop System, 12L Capacity, PC Control: with Blender, Powder Station, 3D Metal Printer and Oven, New 2021

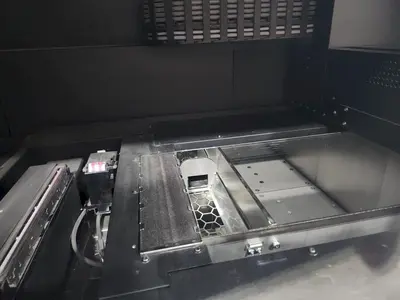

Desktop SHP-PP0009 Metal 3D Metal Printing Shop System (2021)

CNC Control: yes

Type of CNC Control: Desktop Shop System Control

Print technology: Binder Jetting

Print direction: Uni-directional

Maximum throughput: 800 cc/hr

Layer thickness: 50 μm - 100 μm

Native printhead resolution: 1,600 dpi (1 pL native drop size)

Dimensional tolerance of parts: ± 2.0%***

Binder jetting module: 70,000 nozzles (5x redundancy)

BUILD ENVELOPES: 12L - 350 x 222 x 150 mm (13.8 x 8.7 x 5.9 in)

Dimensions: External dimensions (W x D x H) 1,990 x 760 x 1,630 mm (78.3 x 29.9 x 64.2 in)

ELECTRICAL: Power requirements - 100-120V, 12.5A. 220-240V, 5.6A. 50/60 Hz, 1.03 kW

Key benefits

▪ Turnkey system, from printing through sintering

and powder recycling

▪ High resolution printing (1600 dpi)

▪ Maximum throughput of 800 cc/hr

▪ Configurable build envelope

▪ Print previously inaccessible complex geometry

▪ Flexible production from low-volume batches through

mid-volume production

The Shop System™ is the world’s first metal binder jetting system

designed specifically for machine shops—enabling shops to easily

produce parts with exceptional surface finish and resolution at scale.

With production rates of up to hundreds of green parts per day,

the Shop System™ produces parts up to 10x faster than laser powder

bed fusion*. Employing a ~1 pL droplet size, the Shop System™

achieves superior surface finish, bleed control and rich feature detail

at high speed. The Shop System is now available in three packages,

enabling reductions in operating costs and material flexibility for high

throughput customers.

We use cookies to improve your experience. Privacy Policy.