Installed May 2019 Never Ran Production, Never Tooled UP, Save Almost Half the Cost of a New Machine ! Mill-Turn Center with 12,000 RPM B-Axis Articulating Milling Head, 12 Station Live Tool Lower Turret, 80 Station ATC, 1000 PSI High Pressure Coolant, Air Chuck with 5.5" bore, LNS Servo S3 T-L Quick Load Barfeed

Doosan Puma SMX3100ST Multitasking CNC Lathe (2019)

Max Machining Diameter Upper / Lower: 26" Max Turning/Machining Diameter (Main Spindle)

Max Machining Length: 60.6" Max Turning/Machining Length

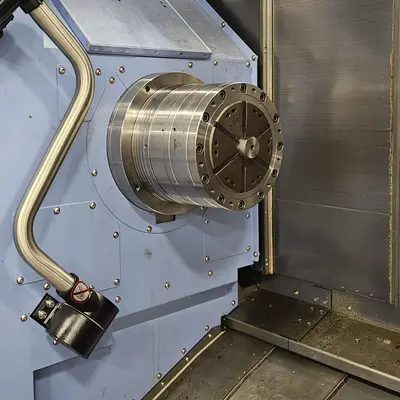

Main Spindle Chuck Size: Samchully Hch-18 18" 3-Jaw Chuck

Main Spindle Speeds: 3000 Max Rpm

Main Spindle Drive: 40 Hp

Main Spindle Nose / Bore: 4.1" Bore, Current Spindle Liner Setup Is Configured For 2.875" Bar Capacity

Main Spindle Indexing: Full C-Axis

Second Spindle Chuck Size: Samchully Mh-212 12" 3-Jaw Chuck

Second Spindle Speeds: 4000 Rpm

Second Spindle Drive: 35 Hp

Second Spindle Indexing: Full C-Axis

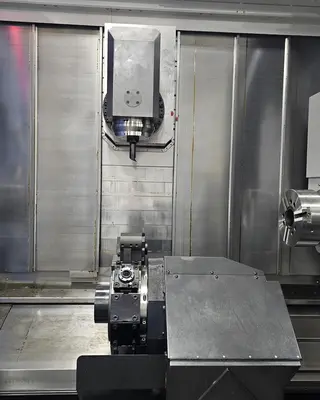

Milling Head Speeds: 12,000 Max Rpm

Milling Head Drive: 35hp

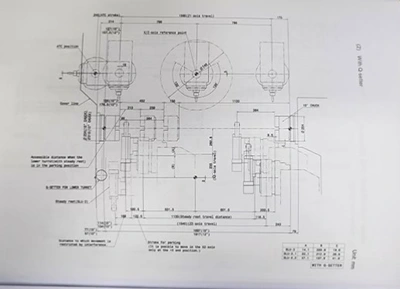

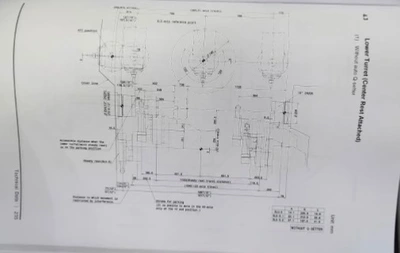

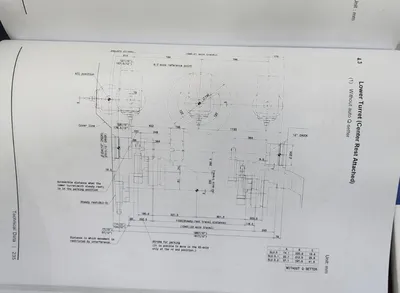

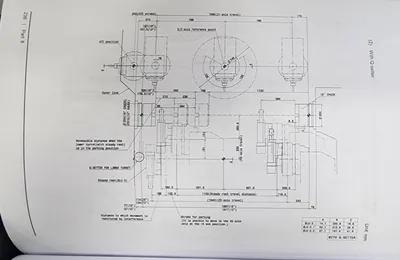

Milling Head Travel X / Z / Y: 27.4" / 62.4" / 11.8"

Milling Head B-Axis Programmable: +/- 240°

Milling Head Taper: Capto C6

Automatic Tool Changer Capacity For Milling Head: 80 Stations

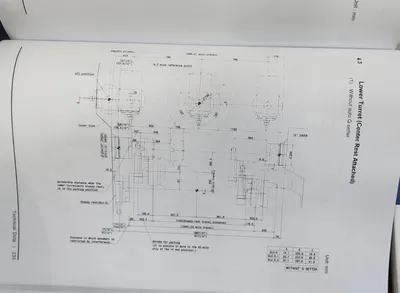

Lower Turret Capacity: 12 Stations, All Live Capable

Lower Turret Travels: 9.3" X / 60.6" Z

Live Tool Speed: 5000 Max Rpm

Live Tool Drive: 9.4 Hp

Rapid Traverse Rates Milling Head (X / Z): 1889 Ipm

Never Ran Production, Never Tooled UP, Mill-Turn Center with 12,000 RPM B-Axis Articulating Milling Head, 12 Station Live Tool Lower Turret, 80 Station ATC, Fanuc Series 31i-Model B5 CNC Control w/ Doosan Easy Operation Package and 15" Display, LNS Barfeed, 12,000 RPM Capto C6 Taper B, Z, & Y Axis Milling Spindle, 80 Station Tool Changer With Tool Library Control Screen, Collet Chuck on Main, Air Chuck with 5.5 Diameter Bore ( on pallet), Samchully MH-212 12" 3-Jaw Chuck on Right Spindle, Full C-Axis on Both Spindles, 40HP Left Spindle, 30HP Right Spindle, Lower X/Z Axis Live Milling & Static Tool Turret with 12 Stations (All Live Capable), Tool Presetter, Renishaw Tool & Parts Probing System with RMI-Q Radio Receiver, RPM600 Parts Probe, Renishaw TRS2 Laser Tool Breakage Detection, Servo Auto Door, 36,000 BTU Coolant Chiller, LNS MF2 Filtering Chip Conveyor with Variable Speed Drive, Complete Coolant System and Tank, Machine Manuals, (3) Capto C6 Tool Holders, (5) Live Tools, Live Tools, and Static Tool Holders,

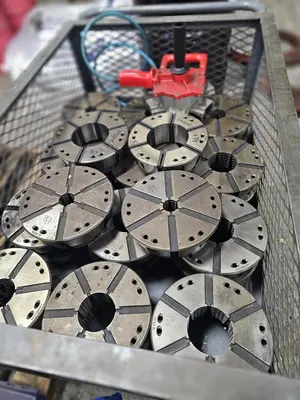

Serrated Collets

1, 1 1/8, 1 1/4, 1 3/8, 1 1/2, 1 5/8, 1 3/4, 1 7/8, 2, 2 1/8 , 2 1/4, 2 3/8, 2 1/2, 2 5/8

2 3/4, 2 7/8, 3, 3 1/8, 3 1/4, 3 3/8, 3 1/2, 3 5/8, 3 3/4, 4, 4 1/4, 4 3/8, 4 1/2,

Smooth Collets, 3 5/8, 3 7/8

We use cookies to improve your experience. Privacy Policy.