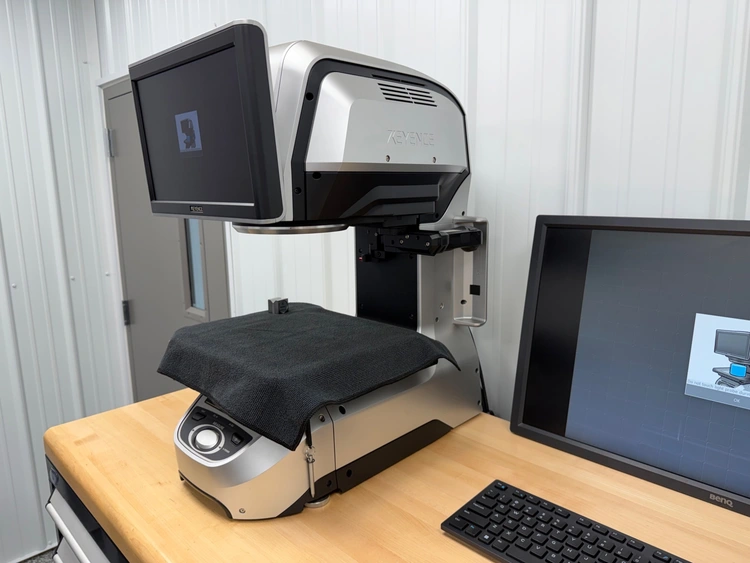

The Keyence IM-8020 is an image dimension measurement system featuring a 20-megapixel CMOS sensor for high-definition imaging, which allows it to measure up to 300 features on a part in seconds. Key specifications include an accuracy of +/-2µm and an automated "place and press" operation that eliminates the need for operator experience or manual datum setup. The system also supports automated 360-degree measurement with an optional rotary unit and can measure multiple parts simultaneously.

Keyence IM-8020 Image Dimension Inspection CMM System (2021)

Sensor: 20-megapixel CMOS sensor

Accuracy: +/-2µm

Measurement speed: Up to 300 dimensions per program in as little as 1 second

Measurement area: Up to 300 × 200mm for automated detection

Simultaneous measurement: Can measure up to 100 parts at once

Stage movement: Up to 80mm/s

Automated operation: Simply place the part on the stage and press a single button; the system automatically identifies measurement points and adjusts focus.

Ease of use: Designed for operation by anyone, regardless of experience, due to the automated process.

360-degree measurement: An optional rotary fixture allows for simultaneous measurement of all surfaces on a 3D part.

Edge detection: Uses a new algorithm for stable edge detection and can automatically remove burrs and chips from the measurement process.

Program selection: Programs can be automatically loaded by placing a QR code from an inspection report on the stage.

High-resolution imaging: Offers triple the detection performance of conventional systems through the combination of the high-resolution sensor and new edge detection algorithm.

We use cookies to improve your experience. Privacy Policy.